About

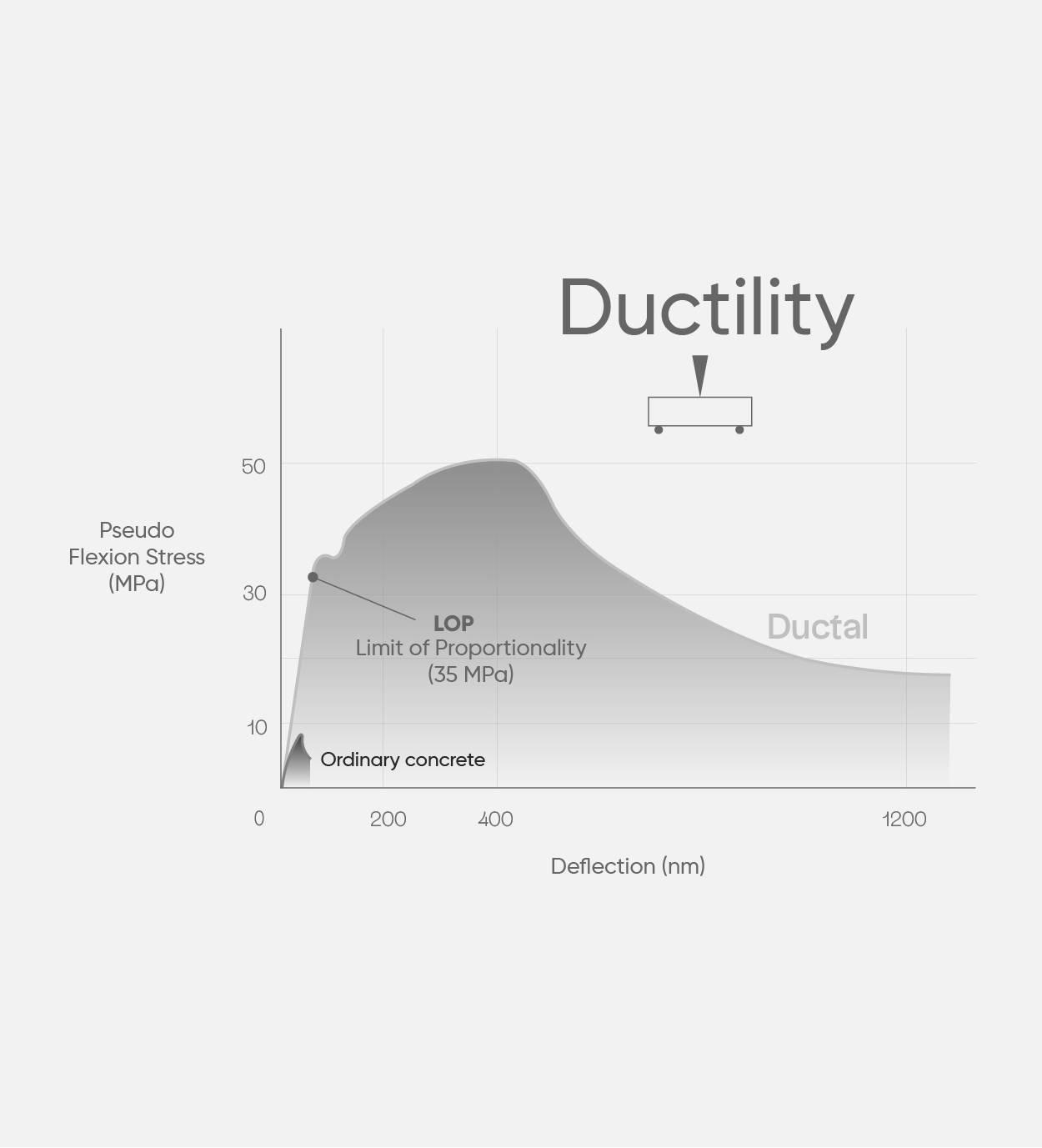

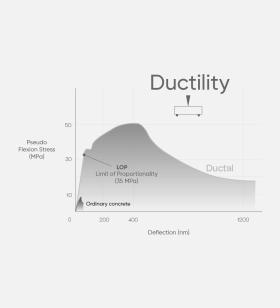

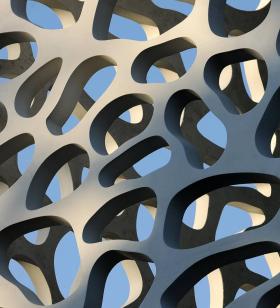

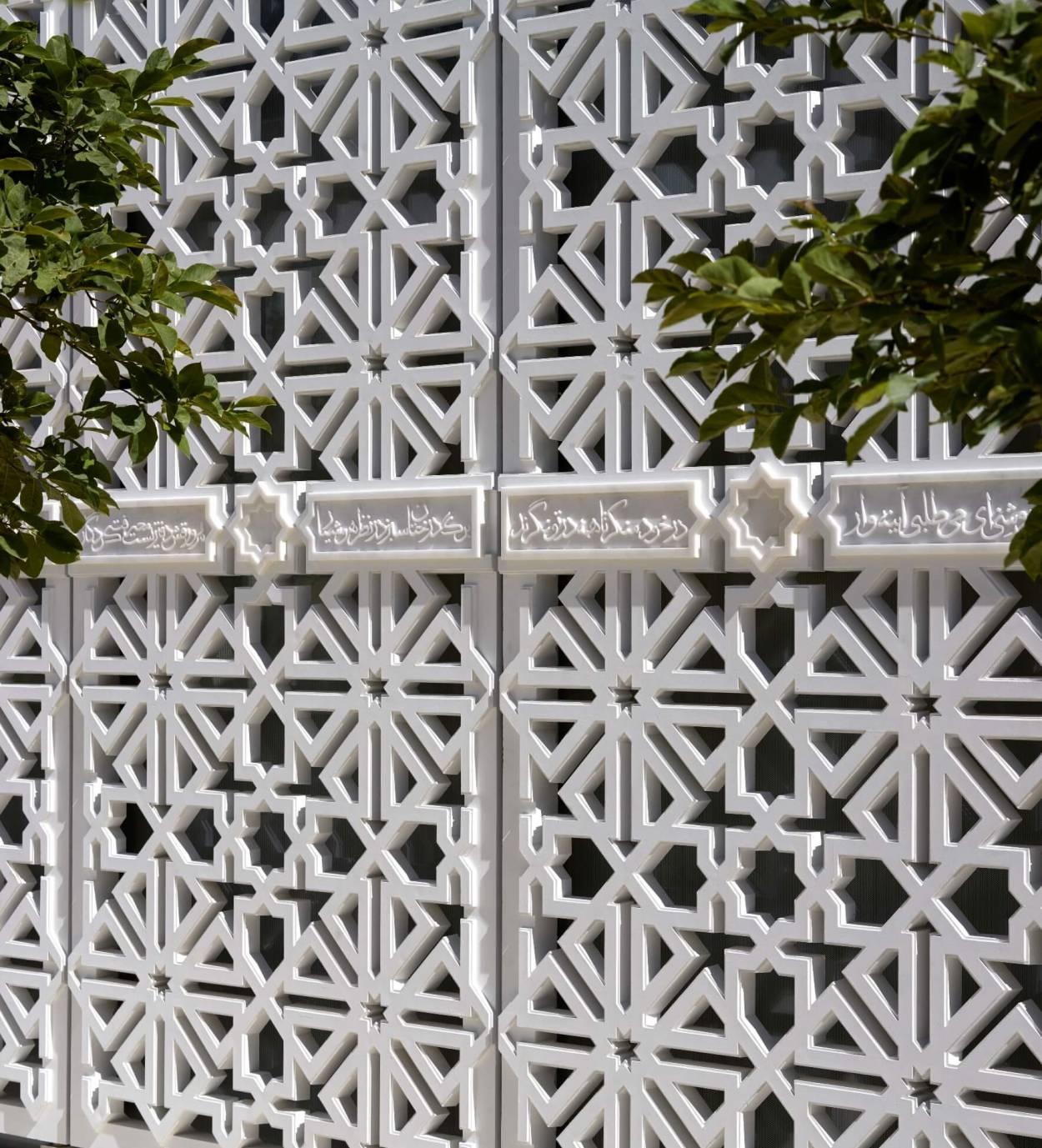

For more than 25 years, we’ve been producing the most advanced range of Ultra High Performance Concrete technologies and services. Born from the desire to minimize inputs while maximizing performance, Ductal® stands for optimal strength, ductility and durability. Decades of global practice, research and development have allowed us to acquire the technology and expertise needed to bring the most ambitious projects to life —without a hitch, anywhere in the world. Our team consists of a diverse collective of licensed engineers, architects, construction consultants and field technicians — all working directly with our clients to develop tailored but pragmatic answers to some of the most important questions in the construction industry today. By inventing construction materials that use less and last longer, we’re enabling more responsible built environments that lift up communities while being more respectful to their natural environment. For the sake of people and the planet we all depend on, we’re bringing concrete solutions to tomorrow’s challenges.

Logistic & Supply chain

Technical support

Logistic & Supply chain

Technical support

Logistic & Supply chain

Technical support

They trust us

Displayed title

AB

Displayed title

Aecom

Displayed title

AFGC

Displayed title

Allied Works

Displayed title

Arcadis

Displayed title

Artelia

Displayed title

Arup

Displayed title

BS&A

Displayed title

Buro Happold

Displayed title

CCFAT

Displayed title

Cerema

Displayed title

CNR

Displayed title

Concrete Pathology

Displayed title

Congrès de l'IDRRIM

Displayed title

DIR

Displayed title

Egis

Displayed title

Etanco

Displayed title

Foster + Partners

Displayed title

Gehry Partners, LLP

Displayed title

Guard industries

Displayed title

IFSTTAR

Displayed title

INGPHI

Displayed title

Keil

Displayed title

Mace

Displayed title

Maki and Associates

Displayed title

MVRDV

Displayed title

Ramboll

Displayed title

SETEC

Displayed title

Sheppard Robson

Displayed title

Simpsonhaugh

Displayed title

SNCF

Displayed title

STRRES

Displayed title

SYSTRA

Displayed title

Wilkinson

Displayed title

Wilmotte

Displayed title

Zaha Hadid