Information

Paris, France

2014

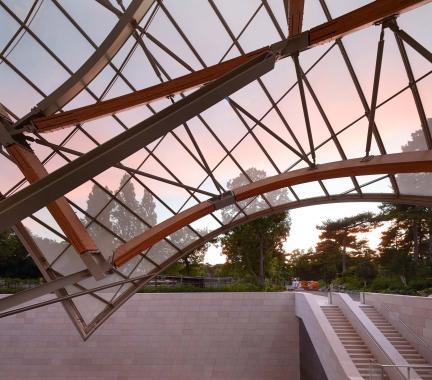

Frank Gehry

Envelope

The Canadian-American architect Franck Gehry, laureate of the Pritzker Architecture Prize in 1989, has designed a building swathed in an array of vast glass sails (large glass surfaces) and consisting of concrete facades with geometric shapes as original as they are complex known as icebergs... Icebergs dressed in Ductal® Envelope, using a unique manufacturing process that has received an award from the French Fédération de l'Industrie du Béton.

Discover our projects

Displayed title

Aga Khan Centre

Aga Khan Centre

Pritzker Prize-winner Fumihiko Maki has completed an educational centre, with a series of roof spaces, terraces and courtyards for the Aga Khan Foundation in London. A project achieved with the use of Ductal®. Each year, the foundation organizes the Aga Khan Award for Architecture, one of the world's most prestigious architecture prizes.

Displayed title

Gasholders King’s Cross

Gasholders King’s Cross

Located in the heart of London, King’s Cross is home to one of the largest urban redevelopment projects in Europe. Preserving the city's industrial architectural heritage, while making it suitable for modern urban living has been a key priority. Ductal® Envelope brought a special touch to the renovation of the historic “gas holders,” turning them into 145 new residences, a stunning and distinctly British architectural project.