Information

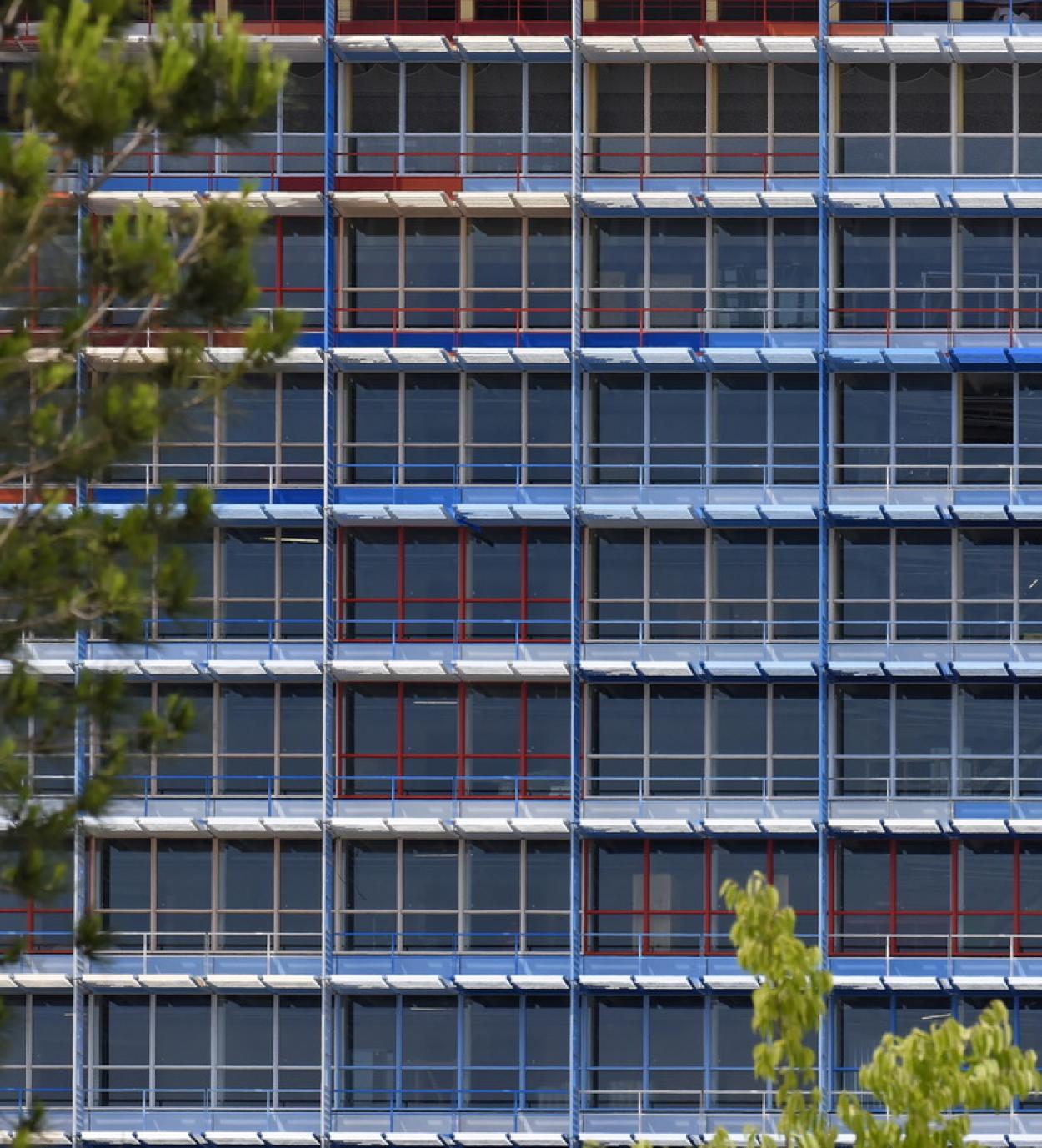

Marseille, France

2018

Jean Nouvel

Archistructure & Fire +

Designed by Jean Nouvel, La Marseillaise marks a real turning point for the Mediterranean city of Marseille. Not only does this 135-meter office block demonstrate architectural and technical prowess, it is also a sustainable economic and social project.

Discover our projects

Displayed title

Barts Square

Barts Square

The Barts Square masterplan, developed by Sheppard Robson for Helical, establishes a new urban mixed-use quarter in the heart of the City of London.

Displayed title

Apex House

Apex House

Apex House is part of Grainger’s Seven Sisters Regeneration project located on the corner of Seven Sisters Road and Tottenham High Road in London.163 new residential units across two towers and four townhouses with a mixture of tenures, as well as communal roof terraces, amenity space and a new commercial market space to accommodate the local shops.

Displayed title

Chinese Cultural Center of Belgrade

Chinese Cultural Center of Belgrade

This unique building has been designed by Chinese architects TF 铨赋, Xiaofeng Zhang and Shan Huang, with an inspiration of the ancient Chinese art painting guóhuà.