Compatible solutions

Information

Coming soon

Coming soon

This resource-efficient technological breakthrough opens up a wide array of new possibilities for engineers, architects and construction contractors seeking to speed up the construction process and optimize the design while guaranteeing high performance. The enhanced durability and exceptional chemical and mechanical resistance of our sprayable technology allow to build more and better – with less.

Discover our projects

Displayed title

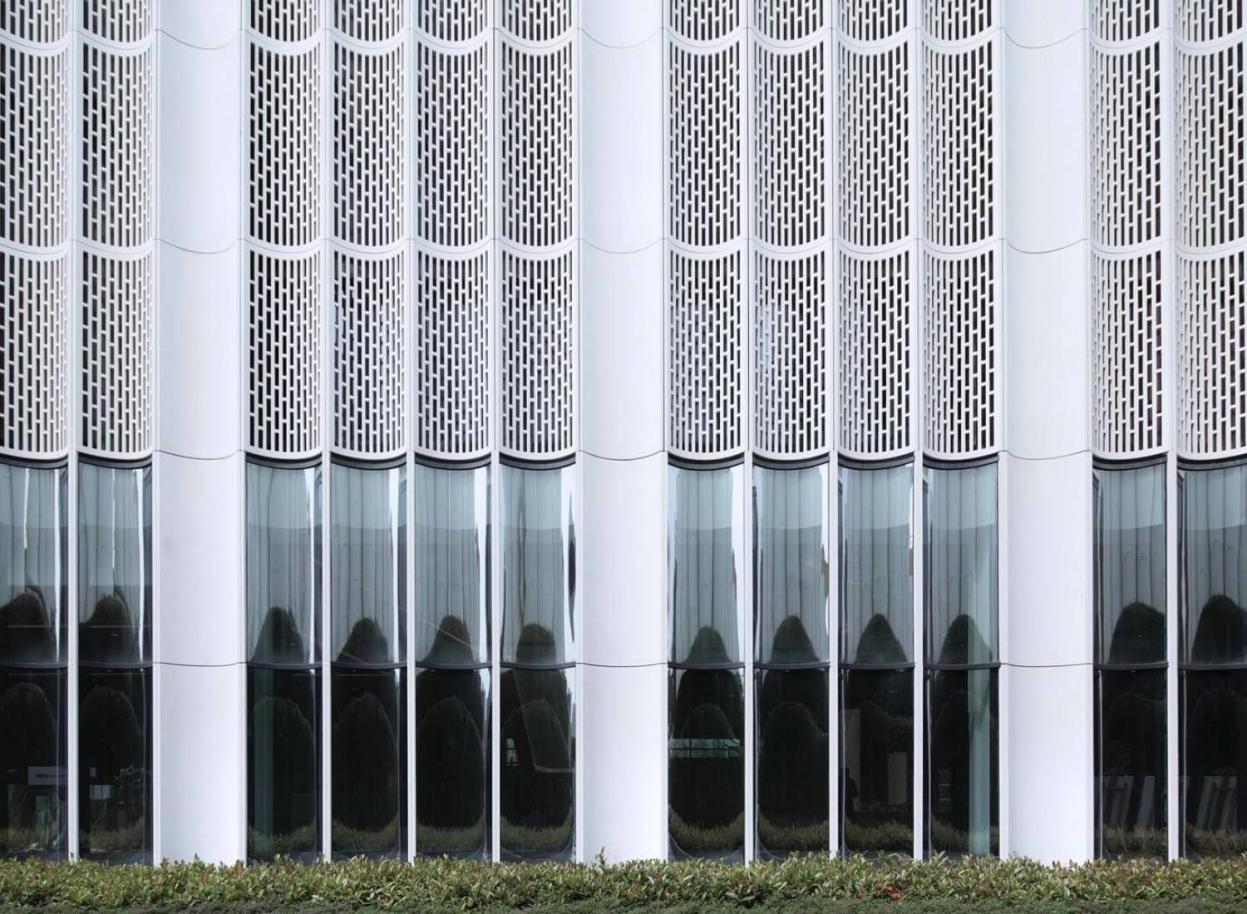

EDF Saclay Campus

The new EDF Campus was inaugurated in 2017 in the Plateau de Saclay business cluster, near the well-known campuses of École Polytechnique and HEC. Built by the architecture firm Emmanuel Combarel Dominique Marrec Architects (ecdm), the building is distinguished by the remarkable volumes of its audacious façades. This technical feat was made possible by the innovative use of Ductal® Envelope combined with Ductal® Spray technology.

Displayed title

Shenzhen Yue Art Gallery

Shenzhen Yue Art Gallery is a renovation project, based on the original Jinwei Brewery District in Luohu of Shenzhen, China. Originally a cans production building, the north portal of the brewery district has been redesigned by BLACKHome Architects.

Displayed title

SHUM YIP UpperHills LOFT

The Shum Yip UpperHills Loft, a Urbanus project, is a high-end commercial complex with 6 high-rise towers containing offices, hotels and business apartments. Adjacent to the CBD and Huaqiangbei shopping district, it is also located between two center parks in Shenzhen.

Displayed title

Great Mosque of Algeria

The mosque combines modernity and authentic design Ductal® was chosen for the facades around the minaret, the roofing of the dome of the prayer hall, the inner courtyard and the covering of the other buildings.